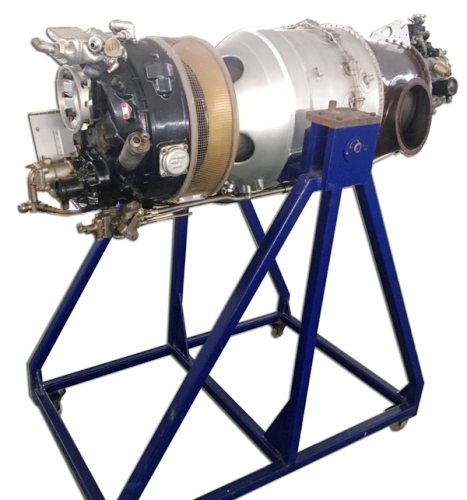

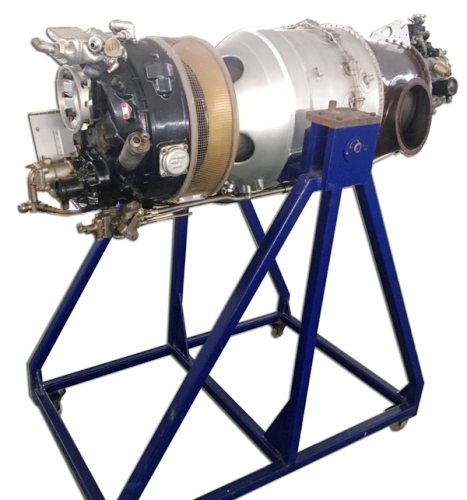

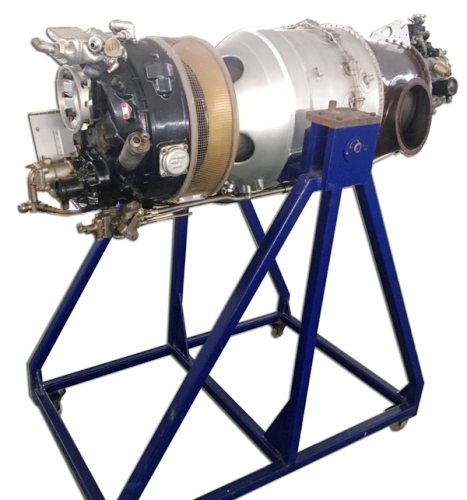

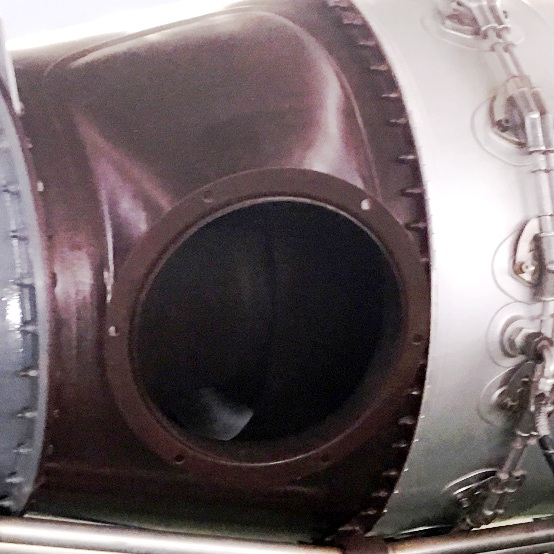

Teardown PT6 Turboprop Engine Trainer AE-08-PT6

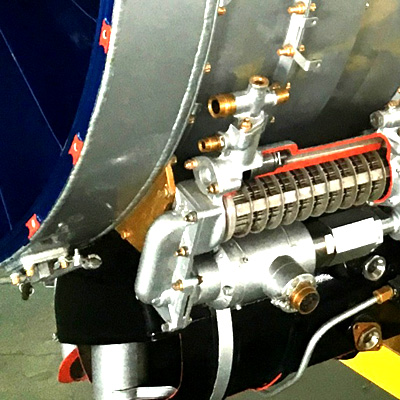

Mounted on a maintenance stand, and it is supplied with hot section inspection tools. The AVIATEK AE-08-PT6A teardown PT6A turboprop engine trainer is used for hands-on training for the dis-assembly and re-assembly of engine parts and sections. With the included tools, the students can perform hot section inspection and a thorough familiarization with engine construction and assembly.

Features

- PT6 Turboprop Engine ready for dis-assembly and re-assembly of engine parts and sections.

- Included Hot Section Tools to perform hot section inspection.

- The engine stand allows easy positioning and convenience in moving the engine as desired.

- Manual and Interactive CBT included.

Components

- Engine Stand

- Hot Section Tools

- Ignition Unit & Leads

- Plugs

- Fuel Nozzles

- Fuel Dump Valve

- Engine Maintenance Manual

- Engine IPC

|

|

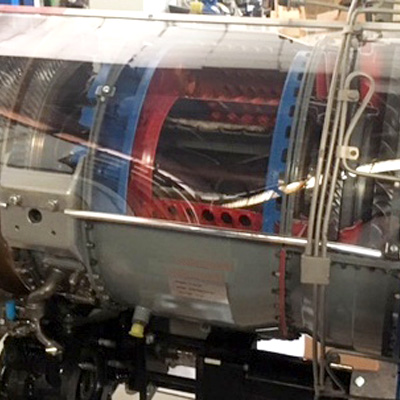

Turbofan CF700 Engine Cutaway Trainer AE-06-700

Motorized with an electric motor and mounted on a roll-around bench-top, The AVIATEK Turbofan CF700 Engine Cutaway Trainer AE-06-700 is a cutaway CF700 low bypass turbofan engine with a physical size of CF700 engine compared to turbofan engines of commercial aircraft, makes it a convenient training aid for turbofan engine introduction.

Features

- Motorized cutaway on engine stand with casters

- Coloring scheme provides easy identification of engine sections

- Cutaway provides a clear view of the Turbine section, Compressor Section, Combustion section

- Manual and Interactive CBT included.

Components

- Fan/Compressor Stages: 1/8

- Core / Power Turbine Stages: 2/1

- Max Diameter (Inches): 33

- Length (Inches): 75.5

- Dry Weight (Lbs.): 725 - 737

- Bypass Ratio: 2.0

- Engine Stand

|

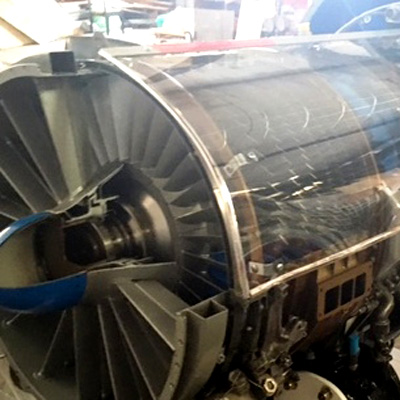

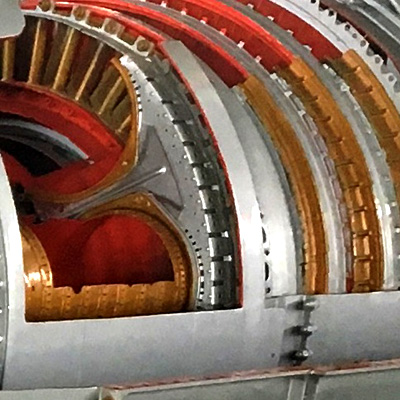

Turbofan Engine JT8D Cutaway Trainer AE-08-JT8

Motorized with an electric motor and mounted on a roll-around bench-top, The AVIATEK Turbofan Engine JT8D Cutaway Trainer is a cutaway JT8D low bypass turbofan non runnable engine with Axial-flow front turbofan (dual-spool), Cross section against ducts, four turbine rotors stages, compressor, combustion chambers, makes it a convenient training aid for turbofan instruction.

Features

- Motorized cutaway on engine stand with casters

- Coloring scheme provides easy identification of engine sections

- Cutaway provides a clear view of the Turbine section, Compressor Section, Combustion section

- Manual and Interactive CBT included.

Components

- Axial-flow front turbofan engine (dual-spool)

- Low bypass turbofan

- Two coaxially-mounted independent rotating assemblies

- Low pressure compressor (LPC) stages: six (six pairs of rotating and stator blades, including the first two stages for the bypass turbofan)

- The second (downstream) turbine stages: Three

- High-pressure compressor (HPC) stages: seven

- The first (upstream) turbine stage: single

- Front-mounted bypass fan (two stages)

- Annular discharge duct for the bypass fan (along the full length of the engine)

- Thrust range from 12,250 to 17,400 pounds-force (62 to 77 kN) (to be determined by engine version and availability.)

- Combustion chambers: Nine

- Combustion Chamber: Can-annular

- Combustion chamber air inlet holes: three (for cooling, burning, and for forming an air blanket)

- Bypass fan diameter: 39.9 inches

- Fan pressure ratio: 1.92

- Overall engine pressure ratio: 15.4

|

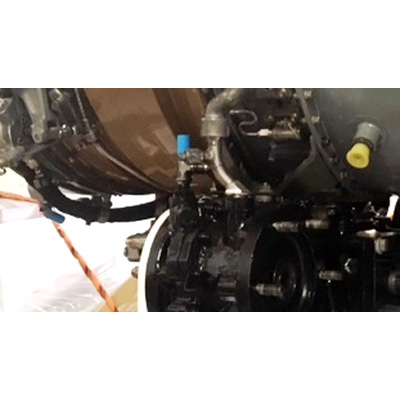

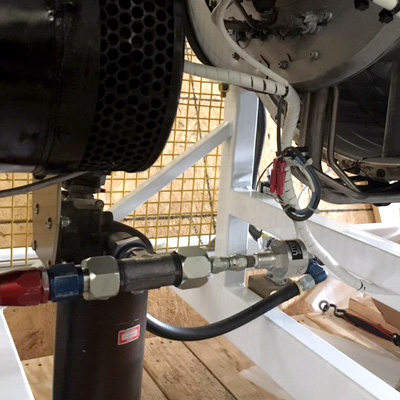

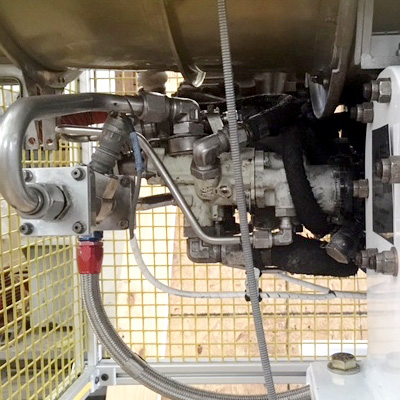

Turbofan CF700 Runnable Engine Trainer AE-33-700

Mounted on a mobile test stand with anchoring points, The AVIATEK Turbofan CF700 Runnable Engine Trainer AE-20-700 is a runnable GE CF700 low bypass turbofan engine, equipped with all associated systems, instruments, and accessories that are needed for operation of a turbofan engine. A safety barrier also included to protects the engine intake area to avoid any accidents.

Features

- Normal engine operation

- Abnormal engine conditions.

- Use of engine bleed air for airframe systems

- Fuel control operation and scheduling

- Ignition system operation and function

- Speed governor operation

- Manual and Interactive CBT included.

Components

- Runnable CF700 Aircraft Turbine Engine

- Engine Stand

- Safety Barrier with Interlocks

- Engine Instrument Panel

- Oil System

- Fuel System

- Engine Electrical System

- Oil Temperature

- Oil Pressure

- Fuel Quantity

- Fuel Flow

- Fuel Pressure

- Engine RPM (N1)

- Fan RPM (N2)

- Exhaust Gas Temperature

|

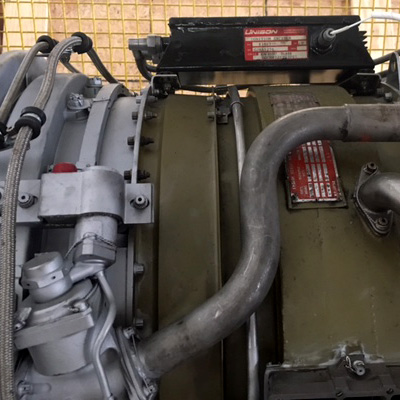

Piston IO-520 Runnable Engine Trainer AE-20-520

Mounted on a mobile test stand with anchoring points, The AVIATEK Piston IO-520 Runnable Engine Trainer is a runnable Continental IO 520 Piston engine, equipped with all associated systems, electrical, blades, instruments, and accessories that are needed for operation of a piston engine. A safety barrier also included to protects the blades area to avoid any accidents.

Features

- (four) towing/lifting hook.

- Delivered Ready-to-Run, Fully tested and Operational.

- Operation Training Manual and Interactive CBT

Components

- Continental Aircraft Piston Engine IO-470.

- Engine : 6-Cylinder

- Engine compression ratio : 6:1

- Cylinder capacity : 400 in3 or 7000 cc

- Power : 200 Hp @2400-2700 rpm

- Fuel type : AVGAS 100 or 100LL

- Fuel : AVGAS 100LL amount 200 liters

- SAE-50 amount 20 liters.

- Protection guard and warning sign.

- Carburetor Heat Box.

- Carburettor of Fuel Injection.

- Fuel Pump.

- Generator or Alternator.

- Magnetos / Ignition Harnesses.

- Starter.

- Propeller, Spinner and Governor.

- Air Filter.

- Complete Test-Cell Wiring Schematic.

- Cowling and Firewall.

- Engine Baffles and Sealing.

- Exhaust Stacks.

- Engine Instrumentation (Engine tachometer, Manifold press gauge, Fuel quantity, Volt meter, Ampere meter, Oil temp, Cylinder head temp, Aircraft clock/Engine hour)

- Aluminum Fuel Tank Capacity 100 liter of Aviation Gasoline.

- Lead Acid Aircraft Battery 24V 25 Ah

|